|

|

|

|

||||||||||||

Our Portfolio! |

||||||||||||

|

||||||||||||

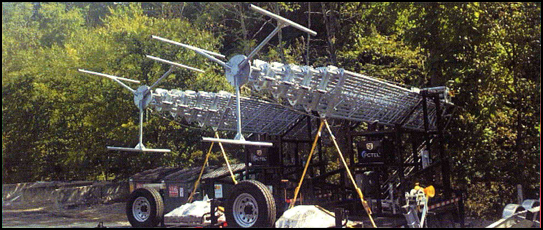

| 2015 Excellence in Hot Dip Galvanizing Electrical, Utility, and Communication Award Winner! Turris Systems Mobile Communications Tower Project Pittsburgh, Pennsylvania |

||||||||||||

Turris is Latin for tower or tall structure. Turris Systems is a manufacturer of mobile towers for the wireless industry. The Mobile Communications Towers are not fixed to permanent foundations, but rather can be moved to areas of need. Turris Systems believes today's wireless network is not the same as the network five years ago; therefore, more innovative solutions to communications towers is warranted. The Mobile Lattice Towers have the capability to deliver high bandwidth wireless LTE data service virtually anywhere needed. The Mobile Communications Towers, more commonly known as "cell on wheels" can be deployed to meet infrastructure needs for the next generation of wireless networks. The new digital world strives for no boundaries, and the cell on wheels provides services as needed at a moment's notice. The Turris System towers are used across many industries such as: mining, oil & gas exploration, surveillance, cellular network expansion, disaster recovery, site lighting, and environmental monitoring, and they offer mobile solutions from 25 to 106 feet. The nature of these mobile systems requires the ability to withstand various environments and the wear and tear of moving between sites. As people rely on these towers to stay connected to the world, it is important they are reliable and long lasting. The owner/designer of the Turris Systems Mobile Communication Towers was looking for a durable coating that could meet the rigors of harsh environments and hot-dip galvanizing was the coating of choice. Hot-dip galvanized steel's metallurgical bond and complete, uniform protection ensure the towers are abrasion resistant and the coating has no weak points. Thanks to hot-dip galvanizing (HDG), these "cells on wheels" will bring clear, consistent coverage whether following an emergency or in a remote location for this generation and the next. |

||||||||||||

|

||||||||||||

| 2010 Excellence in Hot Dip Galvanizing Original Equipment Manufacturing Award Winner! First Energy Summit Project Stratton, Ohio |

||||||||||||

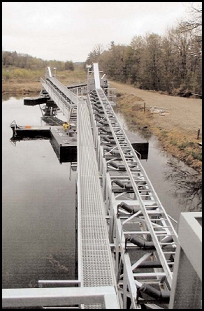

The gypsum pipe conveyor, constructed on the Sammis River site, is a portion of the $1.5 billion project expected to reduce emissions of sulfur dioxide by 95% and nitrogen oxide by at least 64% at First Energy’s largest coal-burning electric generating plant. The 2.4 mile long hot-dip galvanized conveyor stretching through the countryside is part of a hollow rock waste gypsum disposal facility built on a reclaimed strip mine. Limestone is used in the scrubbers as a reagent to remove SO2 from the emissions. During the process, the limestone is converted to synthetic gypsum. The synthetic gypsum is dried and then transported to the facility on the enclosed conveyor belt. The “scrubber sludge” gypsum is then used to make wallboard, further reducing waste. In keeping with these green efforts, utilizing a 100% natural, recyclable zinc coating for corrosion protection means no VOC’s or wasted energy will be expended on maintenance. Hot-dip galvanized steel is highly durable, and will remain maintenance free for 75+ years. Even through the structure’s constant exposure to sun, rain, and snow. The durability of the coating was also necessary because the conveyor was built over steep terrain surrounding the power plant – difficult access for touch-ups and maintenance required by other corrosion protections systems, such as paint. The conveyor also needed a coating that could survive the rough handling conditions of transporting 578,000 tons of limestone annually. Thanks to the dual barrier and cathodic protection of hot-dip galvanized steel, small nicks and abrasions will not compromise the stability of the entire structure. The owners and community desired an attractive appearance for the structure. As much of the conveyor was built on leased property, the owners wanted a clean, consistent look for the machine, which also crosses public roads. The high quality, consistent finish of hot-dip galvanizing satisfied this need. Given the high price tag and the public visibility of this project, the progress of this upgrade will be closely watched. Hot-dip galvanized steel will keep the conveyor attractive, durable, maintenance-free, and running efficiently for decades to come. |

||||||||||||

|

||||||||||||

| 2008 Excellence in Hot Dip Galvanizing Civic Contribution Award Winner! Decorative Flower Boxes Project Women’s Club and Garden Club, West Middlesex, Pennsylvania |

||||||||||||

In a small town in northwest Pennsylvania Amish country, the main thoroughfare through town is now artfully adorned with large galvanized flower planters. A generous donation of time, effort, and material was given to the Women’s Club and Garden Club by Young Galvanizing, Inc. and T. Bruce Sales, Inc. to decorate Main Street in West Middlesex, Pennsylvania. After galvanizing the 2,600 pounds of steel for the flower boxes, the planters were later adorned with a plaque in appreciation of the two downtown merchants, as well as filled with decorative foliage. This donation was not only a gift of the here-and-now, but rather a gift that will continue to give for decades to come, as the boxes will be protected from unsightly rust stains and the everyday wear-and-tear of street traffic. Because of galvanizing’s durability, these planters will look as beautiful 50 years from now as the day they were given to the Women’s Club and Garden Club. |

||||||||||||

|

||||||||||||

| 2007 Excellence in Hot Dip Galvanizing Water & Marine Award Winner! Worthington Products Tuffboom Project Worthington Products |

||||||||||||

For a long time, Worthington Products has relied on the strength of the galvanized coating to provide longevity to the steel products they fabricate. One new product, the Tuffboom, is a floating barrier used worldwide to cordon off waterways. They are commonly used to protect dams from debris and to keep boaters safe and out of spillways and hydro-electric water intakes. However, in addition to protecting the casual boater, they are also used to keep terrorists away from potential targets. Since the attack on the USS Cole, thousands of feet of these barriers have been installed at US naval bases worldwide. The systems require a tough coating as they are in corrosive marine environments and are designed to stop a 15,000 pound speedboat going 50 knots. With the proven track record Worthington Products has had with galvanized steel, the choice was simple. Hot-dip galvanized steel’s superior corrosion protection in marine environments will help keep US Naval personnel, and leisure boaters safe well into the future. |

||||||||||||

| 2004 Excellence in Hot Dip Galvanizing Water & Marine Award Winner! Supreme Manufacturing Eight-Yard Modular Dredge Project Supreme Manufacturing |

||||||||||||

With the objective of designing and building a dredge superior to the competition in performance, uptime percentage, and long-term durability, Supreme Manufacturing had an experience base that suggested there was only one corrosion protection system that would qualify — hot dip galvanizing. Complementing its complete line of raw materials conveying equipment, Supreme Manufacturing integrated 25 tons of hot dip galvanized steel into its eight-yard modular dredge design. Of particular importance was protecting the structural steel of the dredge from the abrasive wear and tear of the sand and gravel encountered during the dredging process. With a 6' x 16' primary screen capable of dredging up to 200 feet in depth, the steel of the dredge is long protected from corrosion and impact damage by the hot-dip galvanized coating. For Supreme Manufacturing, hot dip galvanizing is economical, extremely functional, readily available, and integral to its entire line of highest quality, durable dredging equipment. |

||||||||||||

| 2003 Excellence in Hot Dip Galvanizing Bridge & Highway Award Winner! Fore River Bridge Project Acrow Corporation of America |

||||||||||||

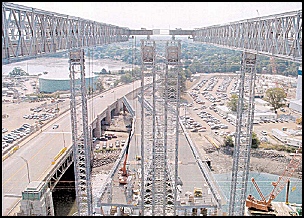

The design, approval, fabrication, and erection of the fabulous Fore River Bridge was an arduous five-year process. Designed uniquely for this site, the Acrow Corporation is one of the few companies that have lift-bridge design experience, making the Fore River Bridge an awesome reality. Acrow chose hot-dip galvanizing to protect the 8,000 tons of structural steel components and fasteners because of its longevity, consistent appearance over many decades, and virtually maintenance-free lifetime. The schedule required three galvanizing companies to supply the durable zinc coating to the structural steel. Working as a team, the three even hand-dipped custom-made components that required special care. Integrated into the design are marvels of electrical and mechanical engineering, working in harmony with the moving steel pieces protected by hot-dip galvanizing. This truly majestic structure is a key element of the 3H highway connecting Boston and Cape Cod, Massachusetts, and will proudly serve for generations. Location: Quincy, Massachusetts Fabricator: Milton Steel |

||||||||||||

Other projects! |

||||||||||||

|

||||||||||||

| Copyright © Young Galvanizing, Inc. All rights reserved. |

||||||||||||